System configurations

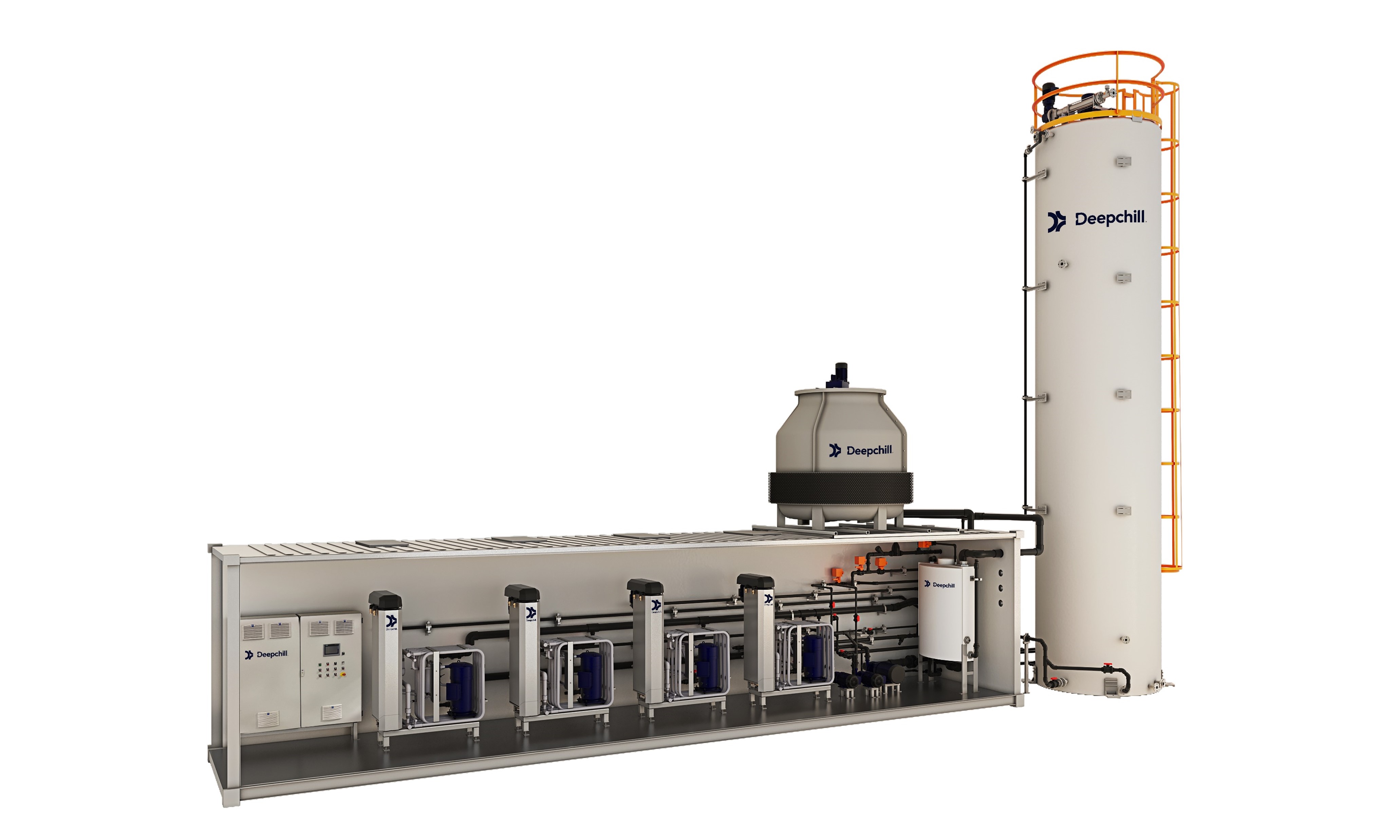

Storage silo-based systems

Silo-based systems feature a passive storage unit. The static storage system does not require continuous agitation or external refrigeration, resulting in low energy consumption.

Key advantages:

- Very low energy losses due to well insulated system

- Minimizes number of generators while enabling handling of peak demands

- Long-term storage of Deepchill® without contamination or bridging

- Less than 2% loss to meltage compared to10% in conventional ice storage

- Can obtain Deepchill® with minimal salt content (approx. 0.5%).

- Allows high-density storage of Deepchill® (at 70% ice fraction), minimizing the storage footprint

- Produces different types of crystals (through recrystallization) for different applications

- Designed based on the FIFO (First In, First Out) method

- Deepchill® can be accurately metered and distributed to multiple locations

Mixing storage-based systems

Mixing storage-based systems feature active storage / dispensers. They require a lower-cost investment compared to silo-based systems

Key advantages:

- Ideal for smaller spaces due to smaller footprint

- Smaller storage capacity, easier to install

- Produce, store and pump up to highly dense 60% ice fraction – minimizing storage size

- The unique re-circulation design provides ability to maintain Deepchill® uniformity and consistency

- Deepchill® can be accurately metered and distributed to multiple locations

- Features insulated tanks with minimal energy losses

Inline systems – without storage

These once-through compact systems deliver Deepchill® inline and can use auxiliary tanks for storage.

Key advantages:

- Lowest investment compared to other systems

- Highly space efficient, fitting into tight spaces

- Provides a very high cooling rate due to type of crystals discharged directly from the generator

- Applicable where steady flow of Deepchill® is required

- Flexibility to operate continuously when processing higher-than-usual capacity