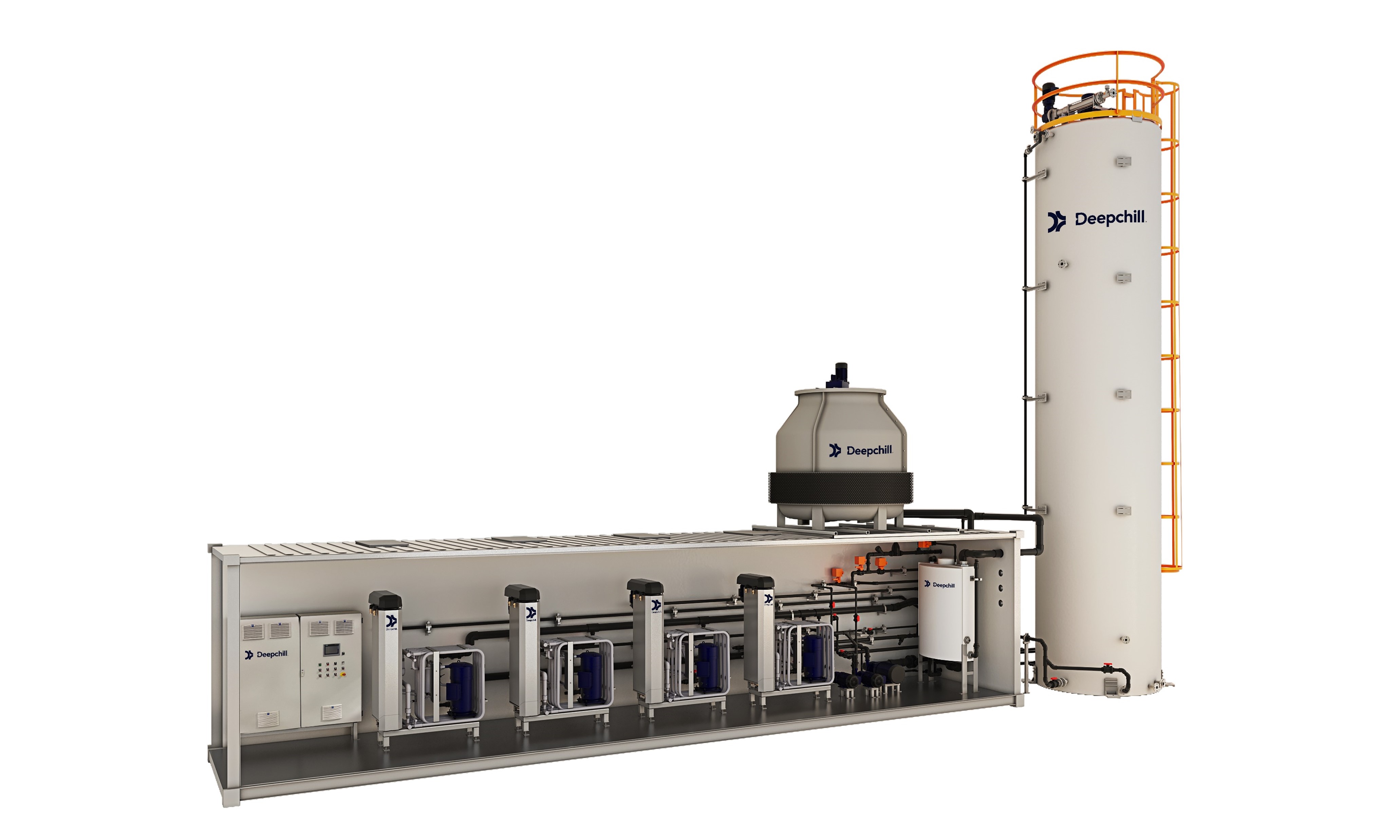

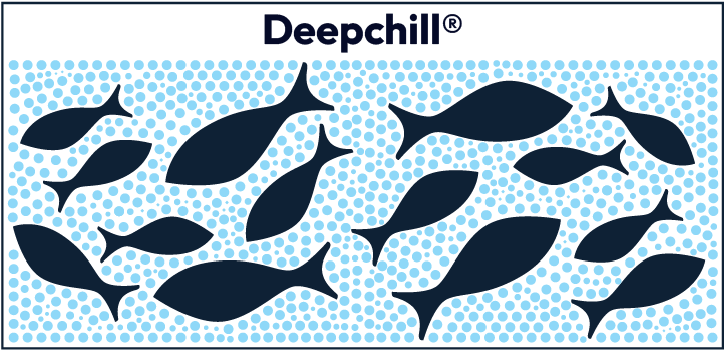

Revolutionary, versatile and highly configurable Deepchill® slurry ice system, adaptable to a range of cooling requirements. Each system may include 3 key components: Slurry Ice Generation, Storage and Distribution, bundled with auxiliary equipment such as Brine Control System and Pre-Chillers.

Watch the video to learn more >