1. Harvest

Live shrimp is uniformly chilled to <0°C in 5 minutes to quickly stop deterioration while also reducing labour and handling.

Cool your product 3 times faster. Shrimp at 24–28ºC can be uniformly superchilled to -1ºC in less than 5 minutes. The shrimp is maintained at an even temperature throughout your entire batch for consistent quality.

Used in either slush or dry form, Deepchill® suspends shrimp and protects it from being squeezed or crushed under pressure. It also preserves the appearance, colour, and firmness, and reduces bacterial growth, resulting in the highest quality head-on shrimp.

Deepchill® helps you simplify and speed up the shrimp harvesting and processing operation, greatly reducing labour requirements and cutting unnecessary steps such as pre-chilling, chemical treatment, or moving ice in the facility. With less steps in the process and much faster cooling speed, your entire operation benefits from a saving in cost and time.

The efficient cooling of Deepchill® lets you cut the ice consumption required at shrimp harvest or processing by 30% or more. It eliminates the need to constantly replenish melted ice or break up clumped ice, saving time and money.

Success story: Improving shrimp production through better cooling

See how Deepchill® helped NAQUA increase production of its top-quality shrimp to meet the demand of high-value markets.

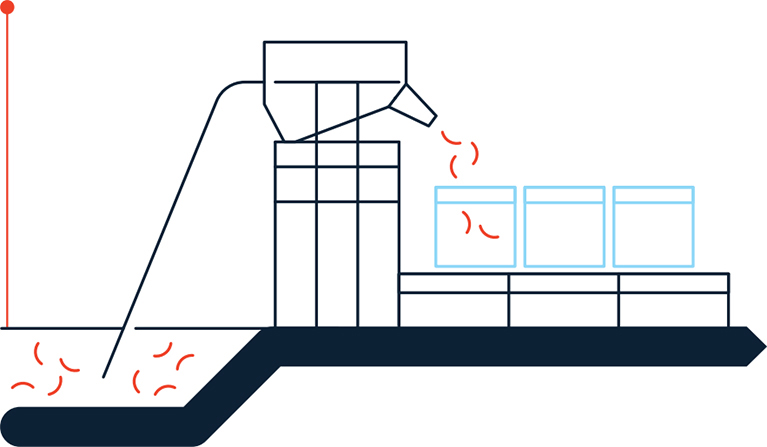

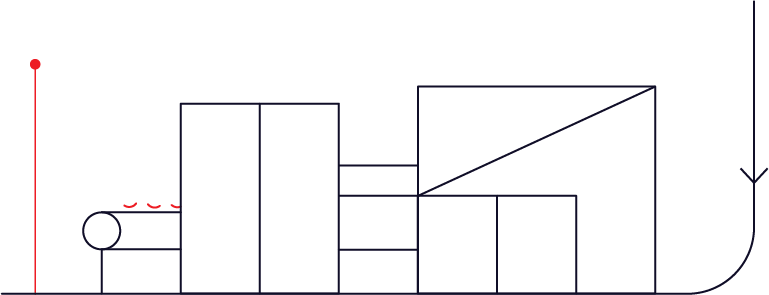

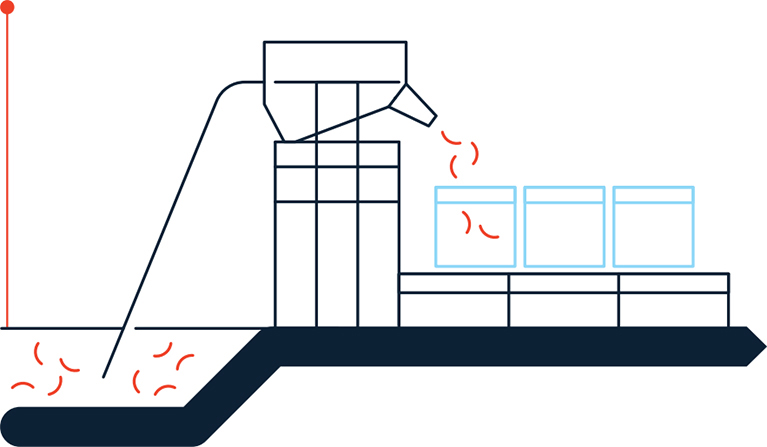

1. Harvest

Live shrimp is uniformly chilled to <0°C in 5 minutes to stop deterioration while reducing labour and handling.

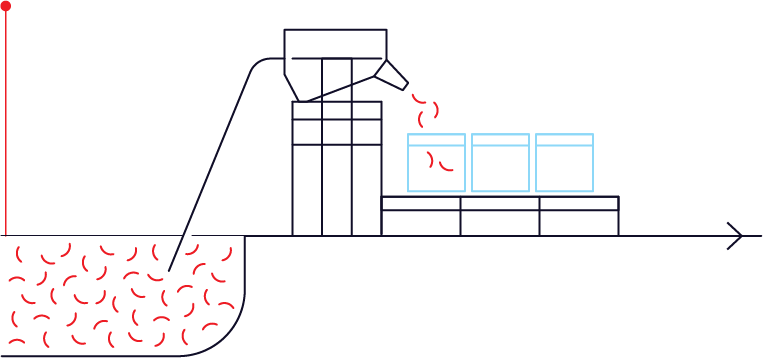

2. Transport

Shrimp is suspended or embedded in Deepchill® to prevent damage and to maintain uniform cooling, ensuring shrimp arrives in the best condition.

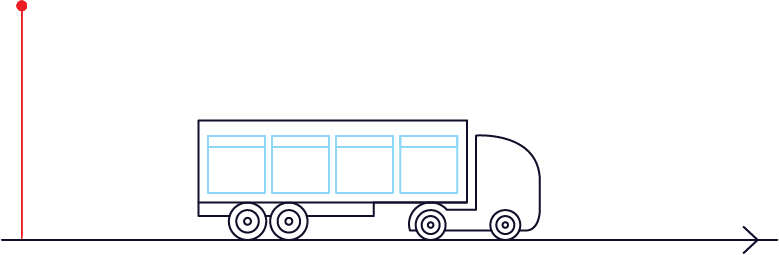

3. Reception

Shrimp is stored in Deepchill® to extend the processing window and to enable better handling of peaks without loss of quality.

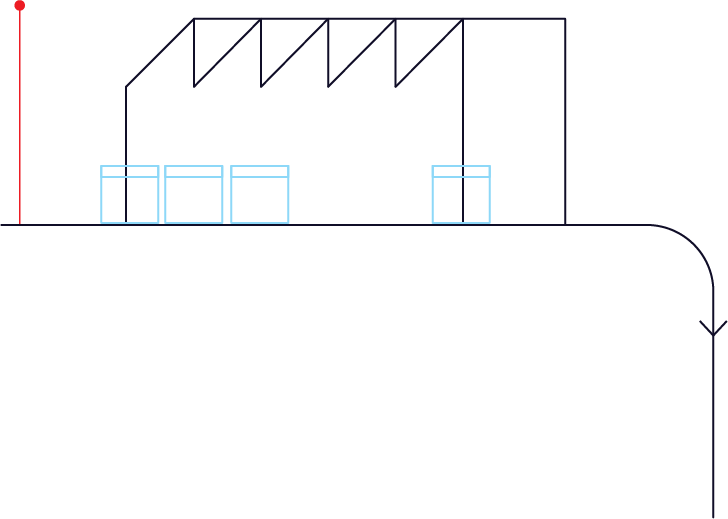

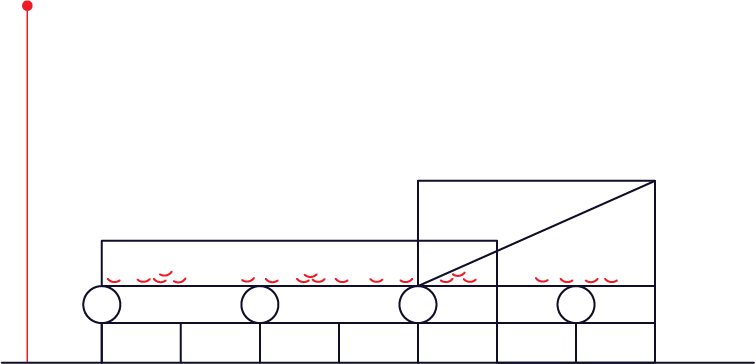

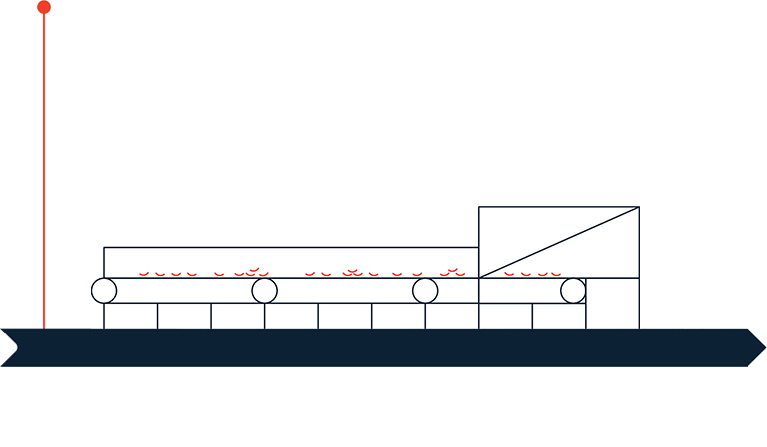

5. Raw Process Line

Deepchill® is pumped where needed, simplifying process and reducing labour. Shrimp is submerged in Deepchill® and maintained at <0°C.

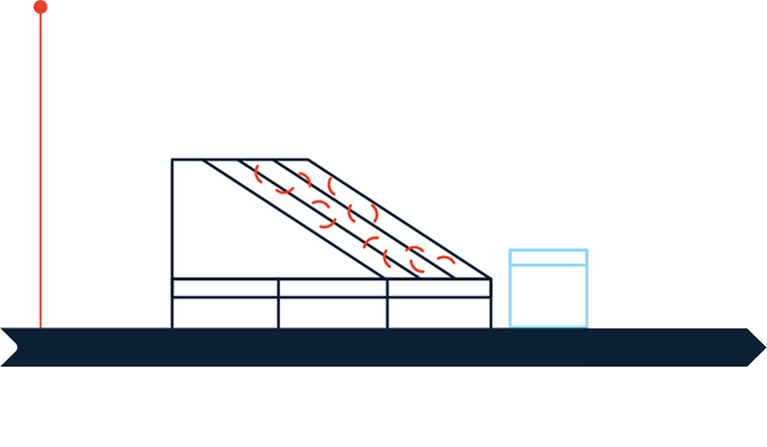

4. Sort

Shrimp is sorted and returned to Deepchill® maintained at -1°C to -1.5°C. Additives can be added directly into bins for efficiency.

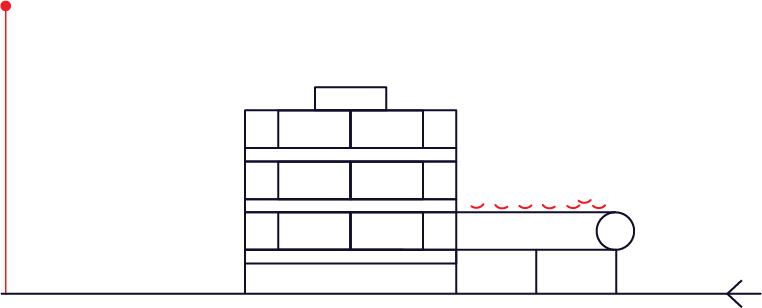

6. Freezer

Improved freezing capacity and efficiency as shrimp is pre-chilled to 0°C before entering freezer, resulting in less shrinkage and higher quality shrimp.

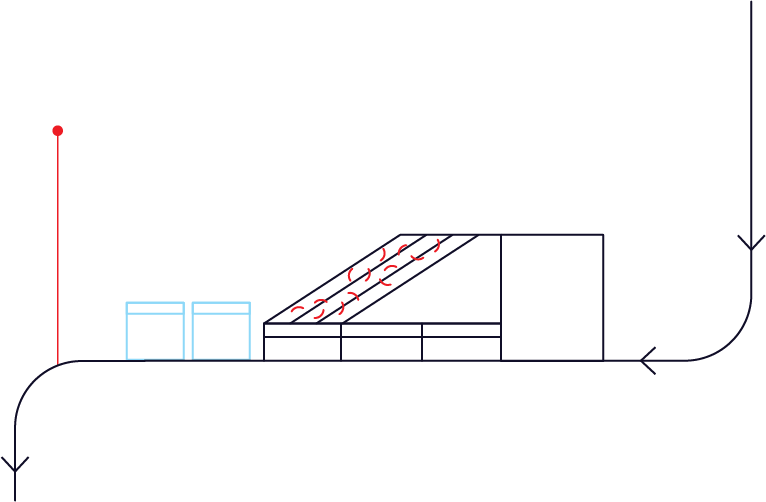

5. Cook and Chill

Cooked shrimp is instantly cooled in Deepchill® to prevent overcooking, bacteria growth and weight loss.

1. Harvest

Live shrimp is uniformly chilled to <0°C in 5 minutes to quickly stop deterioration while also reducing labour and handling.

2. Transport

Shrimp is suspended in DeepChill® or embedded in DeepChill® crystals. This prevents damage and maintains uniform cooling through whole batch, ensuring shrimp arrives in the best condition.

3. Reception

Shrimp is temporarily stored in DeepChill® until processing — this extends the processing window and enables better handling of peaks without loss of quality.

4. Sort

Shrimp is sorted and returned to DeepChill® maintained at -1°C to -1.5°C. Additives, if needed, can be added directly to these bins for a more efficient process.

5. Raw Process Line

DeepChill® is automatically pumped where needed, simplifying process and reducing laborious tasks. Shrimp on the process line is completely submerged in DeepChill® maintaining sub-zero temperatures.

5. Cook and Chill

Cooked shrimp is instantly cooled in DeepChill® to prevent overcooking, bacteria growth and weight loss.

6. Freezer

Improved freezing capacity and efficiency since shrimp is now prechilled to 0°C before entering freezer, resulting in higher quality shrimp and less shrinkage

As a highly perishable product, shrimp is subject to rapid spoilage. Unfortunately, it cannot be undone once it begins. Although it’s impossible to completely stop decay, rapid chilling to sub-zero temperatures significantly slows it down.

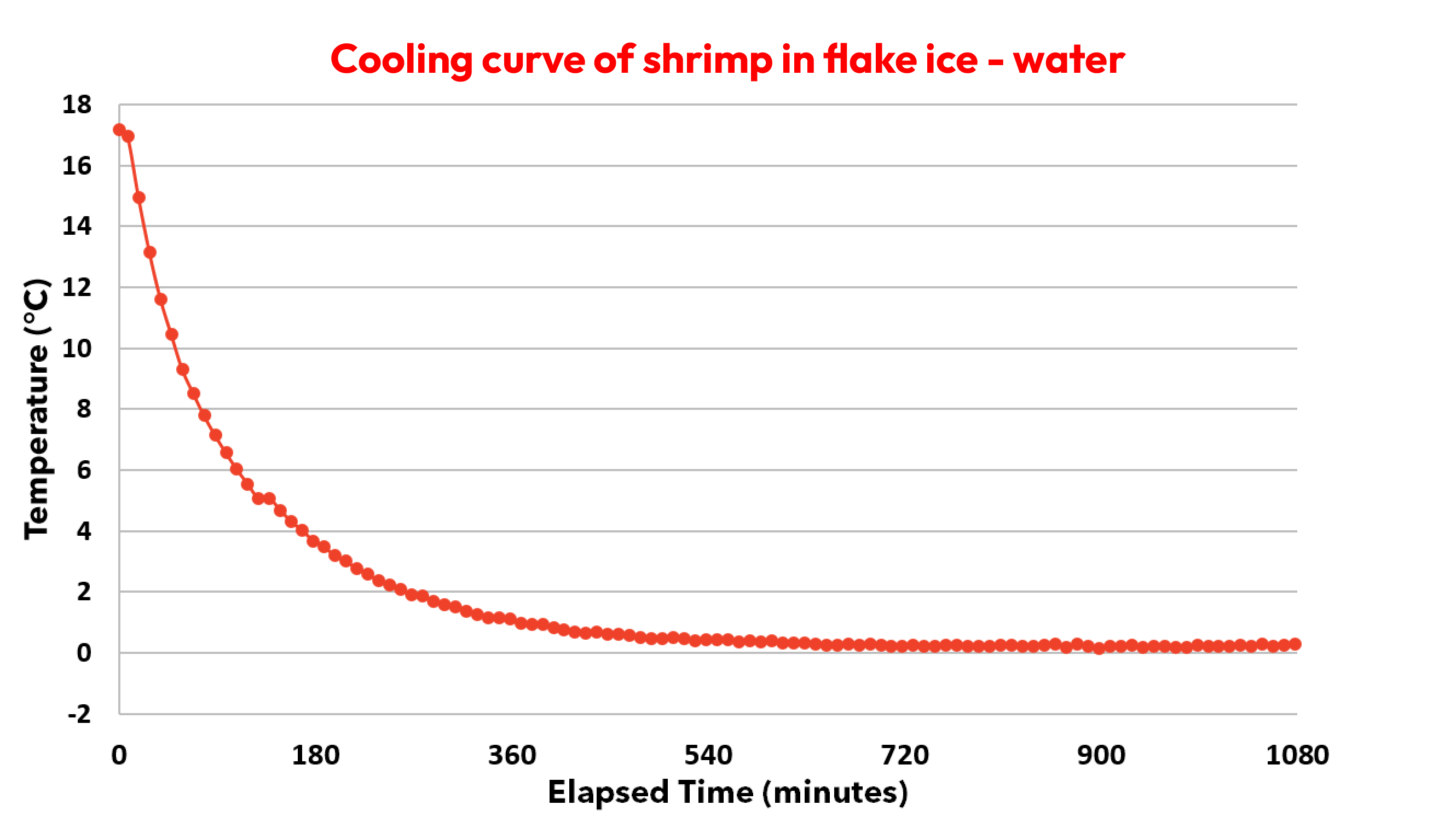

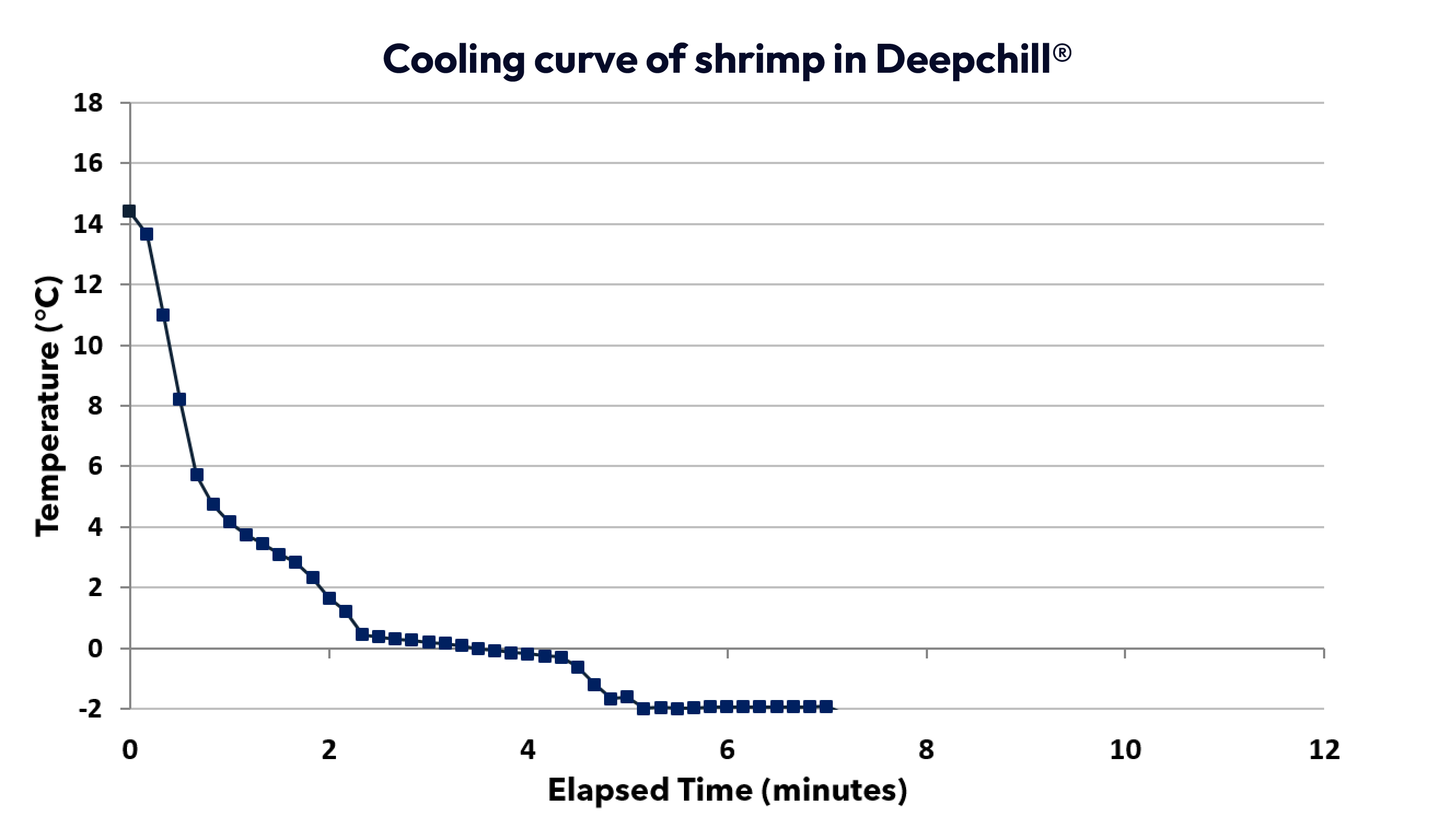

A comparative study of cooling rates shows that shrimp (Pandalus Borealis) cooled in traditional flake ice and water did not reach 0ºC even after 18 hours. By contrast, shrimp cooled in Deepchill® was cooled to a consistent -2ºC in less than 5 minutes. By reducing the time taken to chill the shrimp, and maintaining a constant sub-zero temperature, spoilage is greatly reduced.

Source: Independent study by The Fisheries and Marine Institute of Memorial University of Newfoundland